Description

Certified Quality Steam Sterilizer

Sordina Steam Sterilizers are designed and manufactured in compliance with medical device directive 93/42/CEE, PED directive 2014/68/UE, EN 285, EN 17665, EN 61010-1, EN 61010-2-040, EN 61326. The company quality system is compliant with ISO 9001 and ISO 13485.

The accessories and the solutions designed by our engineers as well as the spare parts have successfully

passed all quality controls.

A solid experience and know-how based on a tradition of more than one hundred years combined with a

dynamic management allow Sordina to customize the products according to the requests.

High-technology, quality and innovation are the milestones of our success and we always look ahead to expand

our business and board our network of sub-contractors and distributors all over the world.

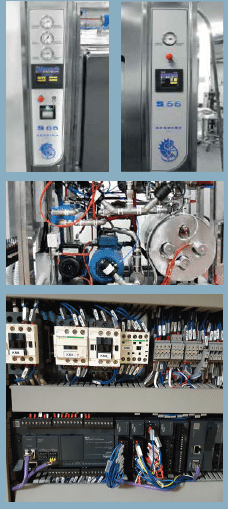

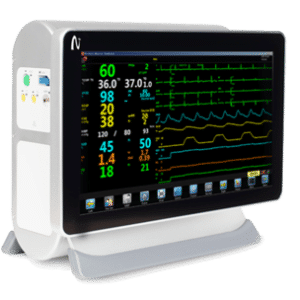

DOUBLE CONTROL SYSTEM FOR DOAUBLE SAFETY

Sordina sterilizers are equipped with two independent units, one for automatic cycle management and one for working cycle control.

The touch screen monitors provide real-time information – graphic and alphanumeric data, alarms and malfunctions- about the sterilization cycle. Programming access directly on site through the control panel using a specific password.

Standard automatic programs EN285 are:

POROUS load, RUBBER load, METAL INSTRUMENTS load, CONTAINER load, LIQUID

and PHYSIOLOGIC SOLUTIONS load (upon request), PRION LOAD. Other 11 open programs are available for customization. Special programs should be installed during unit production at factory or on-site during installation.

All personalized programs should be protected with specific password. Diagnostic programs available as Bowie & Dick and Vacuum test for testing air removal from load seal of sterilization chamber.

The device is also equipped with an ethernet port for external PC connection in order to transfer and print out all data related to sterilization cycles with the STERI-SERV software supervision. Thanks to a compatible software it is possible to manage the process of registration and traceability of the surgical instruments sterilized.

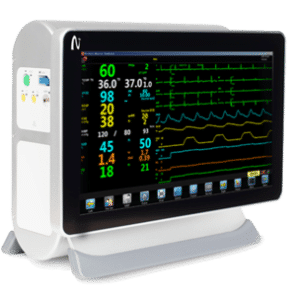

HIGH TECHNICAL PERFORMANCE AND EASY AND QUICK MAINTENANCE.

Sordina sterilizers are designed to guarantee high technical performances and easy and fast maintenance service. There are up to 5 electrical resistances, for example, installed in the front part of the generator so they can be easily replaced.

The cooling system guarantees that the temperature of the discarded liquids never exceeds 40°C.

HIGH QUALITY WATER STEAM STERILIZERS

Sordina Steam sterilizers are the result of several years of experience and know-how in the field of sterilization. The Italian style of Sordina sterilizers is clearly visible in every single component which is accurately designed to achieve the maximum technological performance from the device.

The production of the first models began in 1920 and developed over the years designing some of the most

important sterilization centres in Italy and abroad always taking care of customers.

Sordina is well-known all over the world because of the high quality and technology of its products which are constantly updated and renewed thanks to the collaboration with hospital personnel, experts and technicians.

Originality, attention to details and high-quality components guarantee the safety of the device. Sordina sterilizers can be equipped with 1 up to 8 sterilization units and, in order to respond to customer requests, new

reduced dimension have been designed.

A COMPLETE AND ADVANCED SOLUTION FOR STERILIZATION

Sordina water steam sterilizers are equipped with high capacity sterilization chamber which is wrapped in a stainless-steel isolated jacket.

High-quality melamine resin ensures great thermal isolation so that the external temperature does not exceed 40°C. Sterilization chambers are made of titanium stainless steel AISI316Ti with 10 years warranty in compliance with the highest safety standards.

The stainless-steel isolated jacket, generally made of AISI304, can be also supplied upon request in titanium stainless steel AISI316.

The sterilizer frame and panel are also made of stainless steel with high resistance to AISI304. The double door models are also equipped with 2 touch screen displays on both sterile and non-sterile side showing data related to all sterilization cycles.

For safety reasons, weight and dimensions are now reduced, and the electrical steam generator is separated from the main unit but installed inside the frame. Fast and easy maintenance is also possible thanks to the extractable electrical panel.

AUTOMATIC SLIDING DOORS: all the models are available in configuration with single or double door

AUTOMATIC SLIDING DOORS: all the models are available in configuration with single or double door

(P version) with inflatable movement.Only S336 is equipped with single door.

MAINTENANCE: is fast and easy from the frontal panel thanks to the extractable electrical board

through the telescopic guides.

CHAMBER, JACKET AND DOORS: made of stainless steel AISI316Ti with 10 years warranty in compliance with safety regulation.

GENERATOR: Integrated electrical steam generator made of stainless steel 316Ti, in compliance with PED directive.

LOADED SYSTEM: Apart from S336, all models can be provided with a manual trolley or automatic loaded-unloaded system.

COOLING SYSTEM: guarantees that discarded liquid temperature never exceeds 40°C.

COOLING SYSTEM: guarantees that discarded liquid temperature never exceeds 40°C.

DISPLAY: Colour touch screen display 5.7 LCD STN 320×240 pixel. All double-door models are equipped with a second colour touch screen 3.8 LCD 320×240 pixel on the sterile side.

VACUUM SYSTEM: High performance liquid ring vacuum pump to reduce water consumption.

STEAM GENERATOR OPTIONS: Through integrated electrical steam generator (E); indirect steam (VI) from dirty steam to clean steam; direct steam (V); combination of steam and electricity (EV or EVI). S336 is only available with electrical steam generator (E).

MODULAR CONCEPT: The reduced dimensions allow to easily disassemble the electrical panel through doors 950mm wide.

SAFETY: The operating system is made up of two independent units for the control and registration of working cycles ensuring safety and reliability.

Datasheet For Model S33/S36 /S66 Sterilizer

| Model | STERILIZATION UNIT | CHAMBER SIZE | CHAMBER VOLUME (LITER) | DIMENSIONS LxDxH (mm) | MAXIMUM POWER (KW) | CONFIGURATION DOORS |

|---|---|---|---|---|---|---|

| S336 | 1 | 330x340x643 | 71 | 907x1550x755 | 2-15 | Horizontal sliding |

| S366* | 2 | 330x690x675 | 153 | 920x960x1900 | 2-17 | Horizontal sliding |

| S366*P | 2 | 330x690x690 | 156 | 920x960x1900 | 2-17 | Horizontal sliding |

| S666* | 4 | 660x690x660 | 300 | 1200x970x1900 | 3 - 25 | Vertical sliding |

| S666*P | 4 | 660x690x680 | 309 | 1200x970x1900 | 3 - 25 | Vertical sliding |

| S669* | 6 | 660x690x960 | 436 | 1200x1270x1900 | 3-30 | Vertical sliding |

| S669*P | 6 | 660x690x980 | 445 | 1200x1270x1900 | 3-30 | Vertical sliding |

| S6612* | 8 | 660x690x1260 | 572 | 1200x1570x1900 | 4-31 | Vertical sliding |

| S6612*P | 8 | 660x690x1280 | 581 | 1200x1570x1900 | 4 - 31 | Vertical sliding |

Reviews

There are no reviews yet.